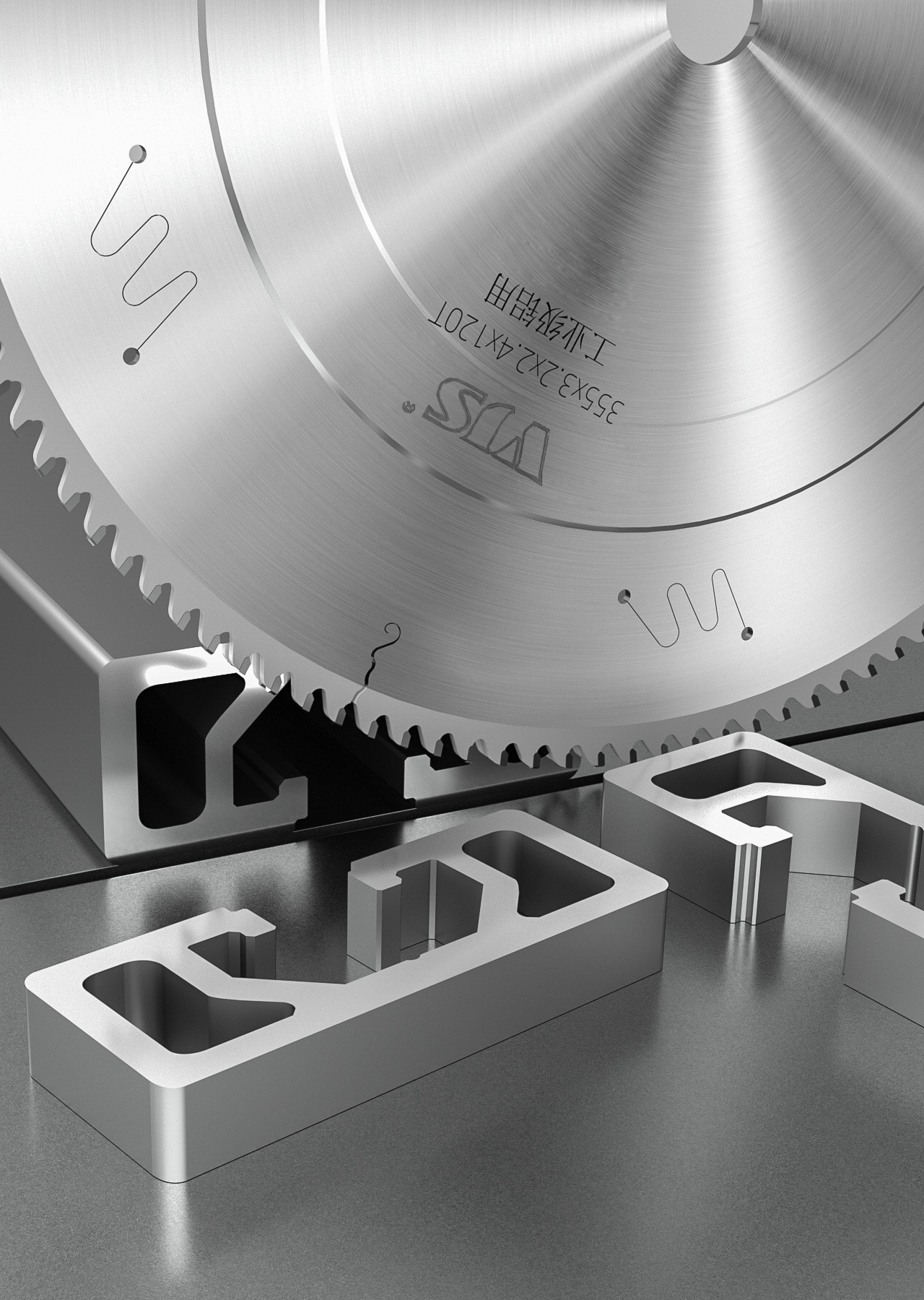

The broken teeth of cold saw blades during cutting are mainly related to the equipment status, operating specifications and maintenance during use. The specific reasons are as follows:

1. Equipment installation problems

· The saw blade is installed eccentrically or loosely, and the vibration during rotation causes uneven force on the teeth and cracks.

· The spindle runout is out of tolerance or the equipment is not rigid enough, and continuous vibration causes fatigue fracture of the cutter head.

2. Incorrect operating parameters

· The feed speed is too fast, and the cutting force surges, causing the cutter head to overload and crack.

· Too low a speed will cause heat accumulation to soften the cutter head, while too high a speed will aggravate the crack propagation due to centrifugal force.

3. Improper cooling and lubrication

· Insufficient cutting fluid causes thermal shock fracture of the cutter head, and the wrong lubricating medium aggravates adhesion and temperature rise.

4. Lack of maintenance

· Continuing to use after the blade is worn, stress concentration expands the gap; incorrect grinding process produces micro cracks.

5. Abnormal working condition operation

· The workpiece is not clamped and stuck, and the instantaneous impact causes the cutter head to crack; over-specification cutting without adjusting parameters causes overload.

Summary: The main causes of broken teeth are equipment accuracy, parameter setting, cooling and maintenance issues. The installation accuracy, feed speed and sufficient cooling must be strictly controlled.