VJS Saw Blade Strength is Recognized By the Southeast Asian Market

From October 1st to October 3rd, 2025, VJS Saw Technology (Jiangsu) Co., Ltd. participated in the Vietnam International Machine Tool and Metalworking Exhibition.

During the exhibition, as a leading domestic manufacturer of HSS circular saw blades, TCT saw blades, and tungsten carbide saw blades, VJS Saw Industry Technology (Jiangsu) Co., Ltd. showcased its three core saw blade series and customized solutions. Leveraging its technological advantages and factory-direct supply model, the company garnered significant attention and established connections with numerous potential customers.

At the exhibition, the VJS team presented the product advantages through physical samples, industry case manuals, and process analysis materials. The general manager personally led the team to communicate in depth with customers and solve production problems in a targeted manner:

Mr. Chen, the technical supervisor at a Vietnamese machinery factory, specializes in processing low-carbon steel bar stock. He had long suffered from rapid saw blade wear and frequent downtime for blade changes. The VJS team recommended the company's HSS circular saw blades: "This saw blade uses a high-quality high-speed steel base. Strengthened by gradient heat treatment, it boasts a 25% longer lifespan than standard HSS saw blades and can reach cutting speeds of 20 m/min, significantly reducing downtime."

After inspecting the saw blade coating and cutting edge details on-site, Mr. Chen immediately arranged to have 20 samples sent for testing, hoping to improve production efficiency through this product upgrade.

Ms. Ruan, the purchasing director of a hardware factory that processes brass pipe fittings, faces the difficult problem of "shavings sticking to the brass when cutting, and the cut surface needs to be manually cleaned."

In view of the processing characteristics of non-ferrous metals, the VJS team recommends dedicated HSS circular saw blades: "We use a special edge grinding process to reduce material adhesion, and the cut surface roughness can reach Ra1.6μm, which can directly eliminate the subsequent cleaning process." After looking through the matching brass cutting case, Ms. Lin was impressed by the results and planned to purchase an initial batch of 30 blades for trial use.

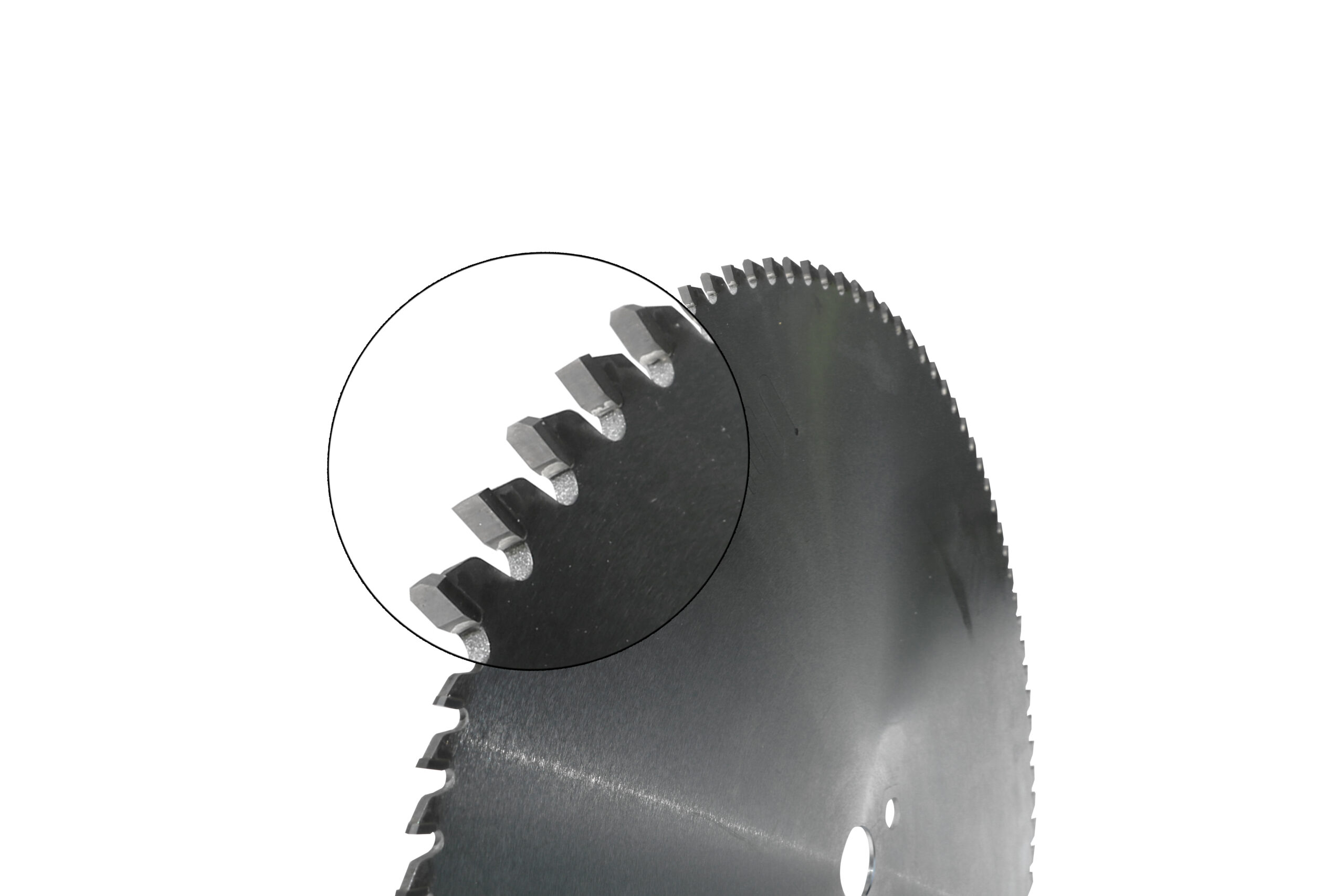

Mr. Huang, from an aluminum alloy pipe factory in Vietnam, has been using imported TCT saw blades, which are expensive and have a long procurement cycle. He wants to replace them with more cost-effective products.

The VJS team introduced the company's TCT saw blades: "They are equipped with imported carbide cutter heads, laser-welded to ensure firmness, with a cutting accuracy of ±0.03mm, and are 30% cheaper than imported ones." After calculating the cost savings, Mr. Huang decided to test 10 samples first. If they meet the requirements, he will sign a long-term purchase agreement.

Mr. Wu, a production supervisor at a Vietnamese auto parts factory, needed to improve the efficiency of their batch cutting of stainless steel flanges (an average of 200 pieces per day). He was immediately struck by the advantages of the high-efficiency TCT cold saw blades: "The optimized blade arrangement allows for 40% faster cutting speeds than traditional saw blades. Even if the blade wears, it can be resharpened 2-3 times, resulting in lower overall costs." After viewing a cutting example video, Mr. Wu immediately placed an order for 100 blades.

Moving forward, VJS Saw Industry will continue to leverage its "source factory" foundation, focusing on saw blade technology innovation and improving production efficiency. This commitment aims to provide global customers with higher-quality, more cost-effective sawing products, fostering in-depth cooperation and mutually beneficial partnerships between the Chinese and Vietnamese manufacturing industries in the sawing sector.