Our offline cutting saw blades are designed for metal cutting and are generally suitable for offline equipment with a speed of less than 120. They are suitable for a variety of metals such as stainless steel, alloy steel, carbon steel, tool steel, and thin aluminum, copper and other non-ferrous metals (special tooth shape is required). Different materials need to match the corresponding saw blade model, please contact customer service.

Please confirm the following parameters:

1. Diameter (e.g. 300mm/400mm)

2. Offline equipment aperture (e.g. 25.4mm/32mm)

3. Online equipment aperture (e.g. 50mm/80mm)

4. Number of teeth (100T/120T/140T...the harder the material, the more teeth)

Provide your machine model or cutting requirements, and we will recommend the best specifications.

1.We support customization! You need to provide specific parameters (diameter/tooth shape/aperture), target material and cutting thickness.

2.Customize according to drawings

3.Customize logo

Our metal ceramic cold cutting saw blades can cut low/medium/high carbon steel, alloy steel, stainless steel, bearing steel, non-ferrous metals (such as copper and aluminum rods and tubes) and other metal materials. They are not suitable for hardened steel or cast iron (easy to break teeth) with hardness > HRC45.

The number of teeth needs to be accurately calculated based on the hardness, outer diameter and wall thickness of the material, combined with the diameter of the saw blade

Thin materials (≤3mm): Calculated with a 315mm diameter saw blade, about 220 teeth, suitable for cutting thin carbon steel pipes and stainless steel thin pipes.

Thick materials (>3mm): Calculated with a 315mm diameter saw blade, about 180 teeth, suitable for cutting thick steel pipes and steel sections.

Soft metals, calculated with a 315mm diameter saw blade, 100-160 teeth, aluminum, copper, low carbon steel.

1. Our ironwork saw blades are specially designed for cutting metal profiles. They can cut threaded steel (HRB335/400, etc.), angle steel, channel steel, I-beam (Q235B, etc.), steel pipes (carbon steel/stainless steel), flat steel, etc.

2. Suitable for metals with hardness ≤HRC45, with high cutting efficiency and not easy to break teeth.

Our aluminum cutting circular saw blade can cut aluminum tubes, aluminum plates, aluminum profiles, aluminum rods, copper tubes, copper rods and other metal materials.

The profiling saw blade moves along a preset track (profiling template) to perform profiling or milling on the workpiece. The saw blade has both "sawing" and "milling" functions and can process complex curves, contours or cavities. Our profiling saw blade is an online track type sawing for pipes.

The copy milling saw blade can cut a variety of metals, including ferrous metals such as ordinary carbon steel, alloy steel, cast iron, non-ferrous metals such as aluminum and aluminum alloys, copper and copper alloys, titanium and titanium alloys, and even precious metals and rare metals.

Our tungsten steel saw blades are mainly made of cemented carbide (tungsten steel), containing tungsten (W), cobalt (Co), tungsten carbide (WC) and other components, with a hardness of up to HRC70 or above. It can cut stainless steel pipes, stainless steel capillaries, copper pipes, aluminum pipes, iron pipes and other metals.

Our tungsten carbide saw blades are used for cutting equipment with a speed of 1500-3000 rpm.

Application Field

From high-speed production lines to specialized material processing, our advanced saw blades deliver unmatched performance across critical industries—ensuring efficiency, accuracy, and durability in every cut.

Offline Cutting Equipment

High-speed steel saw blades are suitable for cutting alloy steel, stainless steel, high-strength steel, iron, copper and other metal materials, and can be used with various offline equipment such as pipe cutting machines.

Online Cutting Equipment

The saw blade of the online cutting flying saw is used for sawing metal materials such as iron and steel hollow round pipes/square pipes, and iron/steel profiled sections on the welded pipe production line, enabling high-speed dynamic tracking cutting.

High Speed Circular Saw Machine

Metal ceramic cold cutting saw blades are suitable for high-speed metal circular saw machines. They can cut medium/low carbon steel billets, stainless steel billets, steel plates and bearing steel. They are widely used in automated cutting scenarios in industries such as steel metallurgy, machinery manufacturing, aerospace, chemical and medical.

Desktop Cold Cut Saw

Ironworker cold-cutting saw blades can efficiently cut various steel profiles and pipes, such as rebar, angle steel, channel steel, I-beams, and steel pipes. They are widely used in scenarios including construction steel structure projects, mechanical parts manufacturing, pipeline installation works, and metal recycling processes, and are compatible with bench-type cold-cutting saws.

Aluminum Cutting Machin

Circular saw blades for aluminum cutting can efficiently cut non-ferrous metal materials such as aluminum pipes, aluminum sheets, aluminum profiles, aluminum bars, copper pipes and copper bars. They are suitable for aerospace, automotive manufacturing, electronics and electrical appliances, architectural decoration, bathroom hardware and other scenarios, and are compatible with equipment such as aluminum cutting machines.

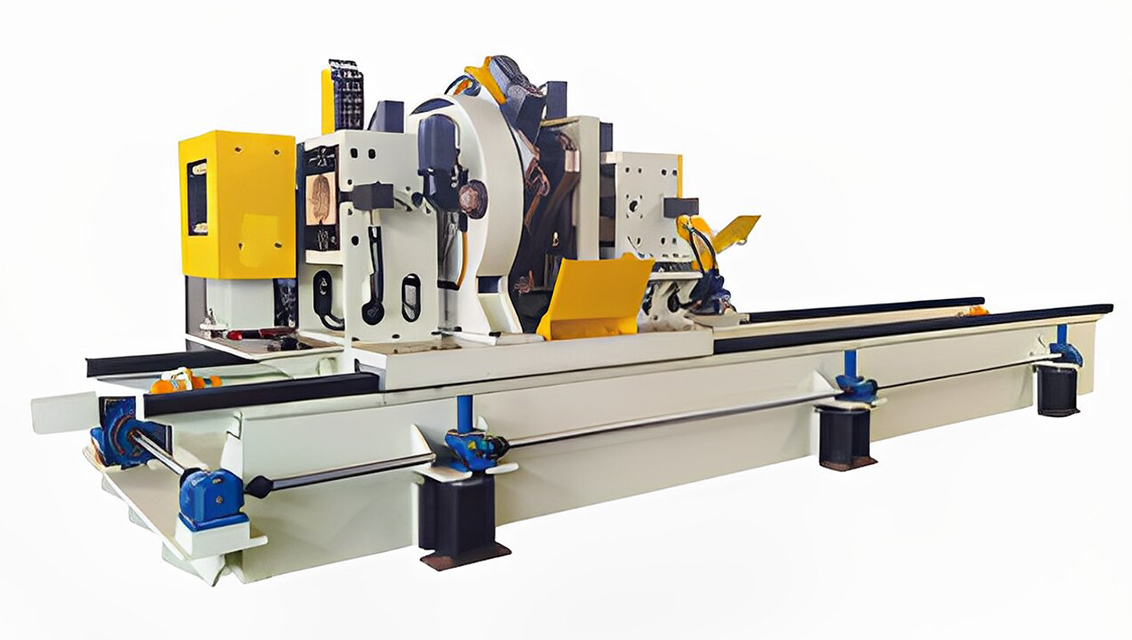

Copy Milling Saw Machine

The profiling milling cutting saw blade can cut carbon structural steel, low-alloy high-strength steel, and steel for oil casing pipes. It is used in scenarios such as oil pipeline bevels and special-shaped steel structure parts, and is compatible with CNC profiling milling equipment. It can follow the contour to cut complex shapes and meet precision requirements.

Cutting Machine

Tungsten steel saw blades are suitable for cutting machines with a speed of 1,500 to 3,000 revolutions per minute. They can cut stainless steel pipes, copper pipes, aluminum pipes, iron pipes, capillary tubes, etc., and are suitable for precision pipe processing in medical devices, electronics, automotive and other industries.