The integral cemented carbide is mainly composed of tungsten carbide (WC) and metal binders such as cobalt (Co). Among them, tungsten carbide is the key component that endows the alloy with high hardness and high wear resistance. Tungsten itself has an extremely high melting point (3410°C), which enables it to maintain stable physical and chemical properties in high-temperature environments, and is crucial for manufacturing tools and components that need to work under harsh working conditions. Its high hardness and wear resistance can significantly improve the cutting performance and service life of integral cemented carbide products.

From the perspective of resource distribution, mineral resources have obvious uneven distribution, and the world's proven tungsten ore resources are concentrated in specific regions. In recent years, affected by factors such as increasing mining difficulty and rising mining costs, the procurement cost of tungsten carbide, the main raw material for integral hard alloys, has continued to increase. In addition, tungsten, as a key raw material, has limited reserves and strong demand, which further promotes the price increase of tungsten, drives up the price of raw materials, and thus increases the production cost of integral hard alloys.

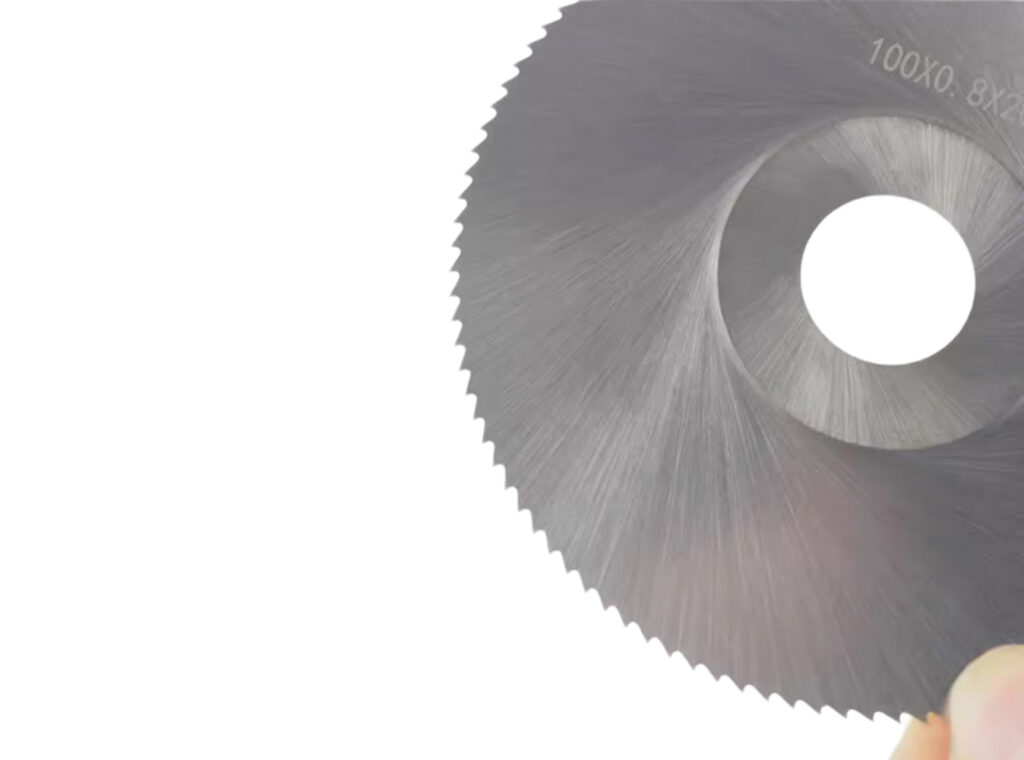

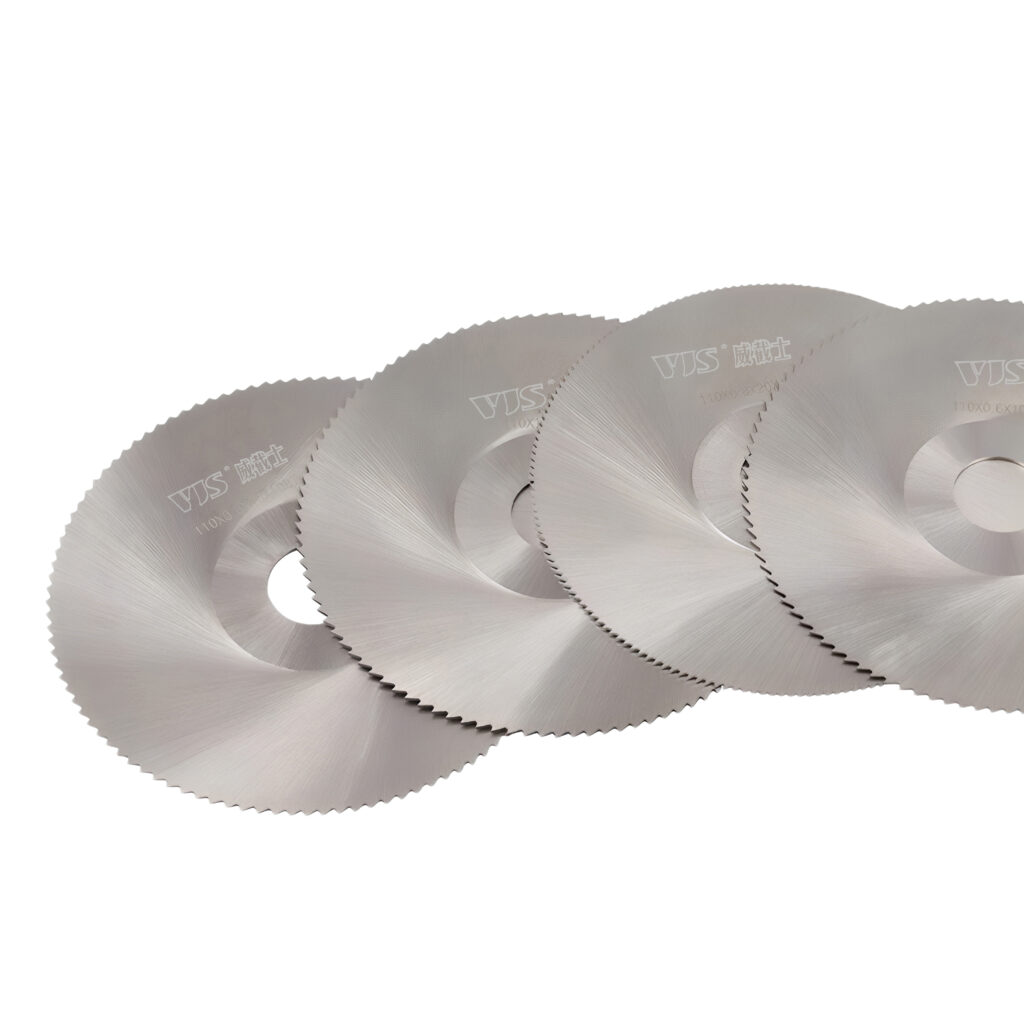

The cemented carbide saw blades of VJS Saw Industry are mainly used in high-end manufacturing fields that have extremely high requirements for cutting precision and efficiency, such as the processing of key components in the aerospace industry, the cutting of precision pipe fittings in automobile manufacturing, and the processing of precision molds. Customers in these fields have very strict requirements for the quality, cutting precision and durability of saw blades, and are willing to pay corresponding prices for high-performance cemented carbide saw blades. Because cemented carbide saw blades can well meet these high-end needs, they also bring about an improvement in production efficiency for customers, help customers gain advantages in market competition, and achieve good market value. However, recently, due to the price increase of tungsten raw materials, the prices of common tungsten steel saw blades on the market have all increased. The saw blades of VJS Saw Industry have also been affected to a certain extent. Nevertheless, we always adhere to ensuring high product quality and try our best to optimize costs to provide customers with more cost-effective products and services.

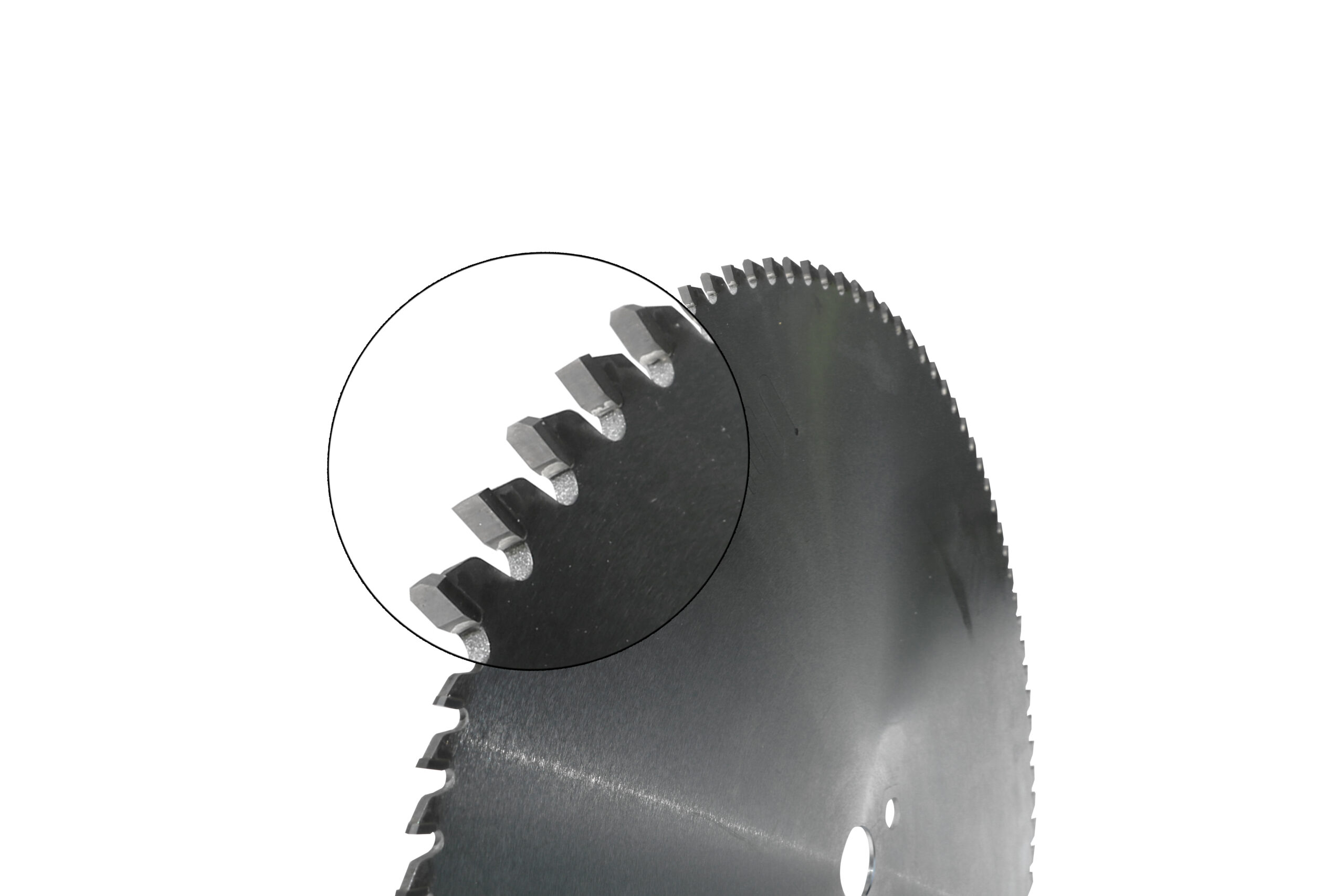

From the perspective of technological research and development, VJS Saw Industry continuously invests resources to optimize and upgrade the production process of integral cemented carbide saw blades. By improving key links such as powder proportioning and sintering temperature control, the performance of saw blades is further enhanced. For example, the hardness distribution of the saw blade is made more uniform, so that it can maintain a stable cutting effect when cutting different materials and reduce abnormal wear of the cutting edge. At the same time, we also continue to innovate in the tooth shape design of the saw blade. According to different cutting materials and scenarios, we design tooth shapes that are more suitable for needs, improve cutting efficiency and 切口 quality, and make the saw blade able to handle complex processing tasks with ease.