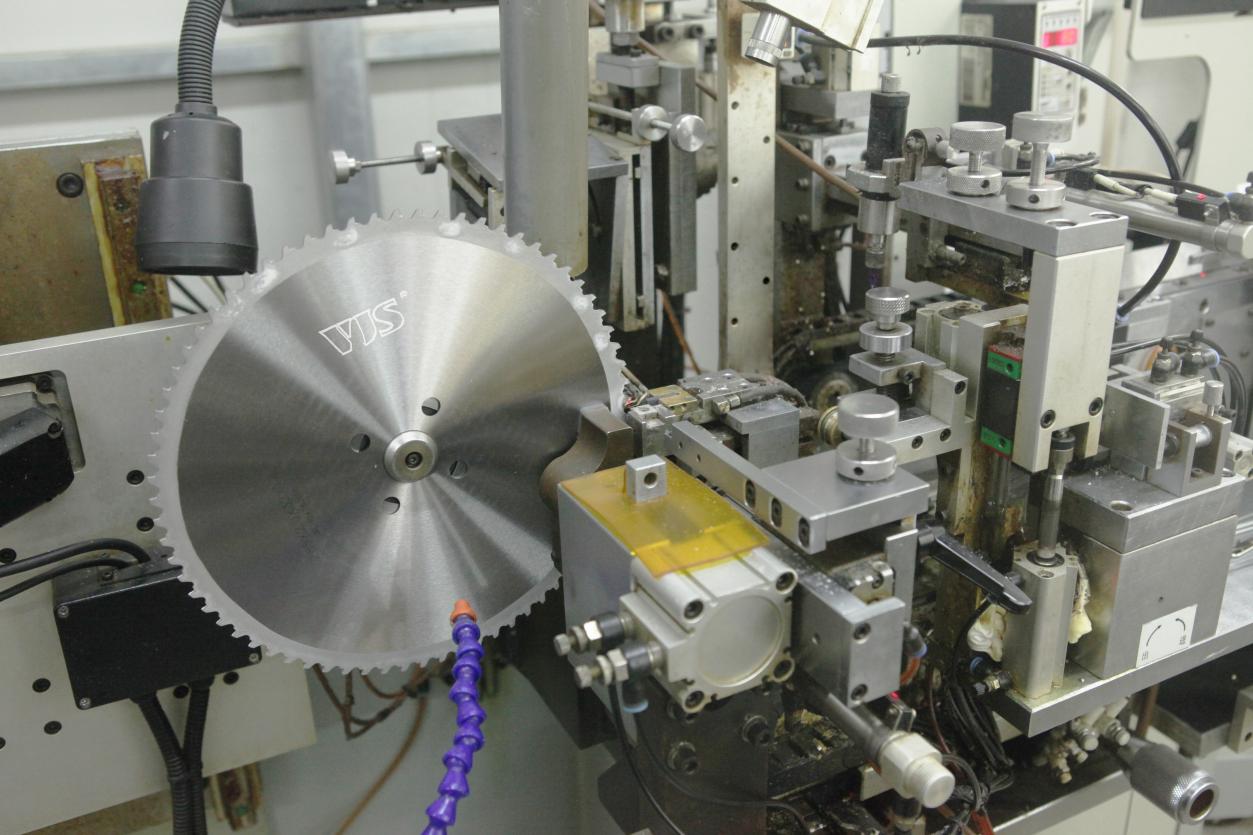

As a cutting-edge tool in the field of aluminum processing, industrial-grade ultra-thin aluminum saw blades have achieved breakthroughs in cutting accuracy, material utilization and processing efficiency with their ultimate design of only 0.1-1mm thickness. They are not only suitable for various types of aluminum, but also show unique advantages in the cutting of copper tubes and copper rods. They are widely used in high-end manufacturing and precision processing fields with strict precision requirements.

The blade head is made of ultra-fine WC-Co alloy, which has a hardness of HRA90-93 after vacuum sintering, and is both tough and anti-chipping. The 65Mn alloy steel matrix eliminates stress and ensures stable high-speed operation at 20,000-60,000 rpm. The ultra-thin micro-tooth design has a cut of 0.1-0.3mm, saving 30%-50% of material. The PCD, TiAlN + DLC coating reduces friction to 0.1-0.2. The anti-stick blade has a thermal conductivity increased by 2-3 times, fast heat dissipation, and a lifespan extended by 2-3 times, making it suitable for continuous operation.

1.Aluminum plate cutting application

Aluminum plates are widely used in industries such as electronic equipment housings and building curtain walls, which have strict requirements on cutting efficiency and precision. The aluminum cutting circular saw blade has a multi-blade thin blade design, which takes into account the processing of aluminum plates of different thicknesses: the thin blade handles thin plates below 2mm to avoid warping and tearing; the high-strength blade handles thick plates above 5mm to ensure stable cutting. With CNC equipment, it can accurately cut complex graphics, significantly improving product quality and production efficiency.

2.Aluminum tube cutting application

Aluminum tubes are widely used in automotive air conditioning pipelines, medical device catheters and other fields, which require extremely high cutting accuracy and surface quality. The aluminum cutting circular saw blade uses a high-hardness blade head and a sharp blade edge to accurately cut aluminum tubes at high speed, ensuring that the cutting does not deform or crack, and the cross section is flat and smooth, meeting the needs of high-precision assembly. For example, in the production of automotive air conditioning pipelines, the saw blade can cut 20-30 times per minute, with a narrow incision, which not only saves pipe materials but also ensures the sealing of the connection.

3.Aluminum profile cutting application

Aluminum profiles are widely used in building doors and windows, rail transit and other fields due to their complex cross-sections, and the adaptability of cutting tools is extremely high. The circular saw blade for cutting aluminum can customize the tooth angle, and can accurately separate the insulation strip from the aluminum when cutting the broken bridge aluminum profile. The cut is neat and convenient for the assembly of doors and windows. In the field of rail transit, the rigidity and stability are enhanced by optimizing the structure, the vibration and noise are reduced, and the large aluminum profile frame is accurately cut to meet the strict processing standards of high-strength structural parts.

4.Aluminum bar cutting application

Aluminum bars are used as machining blanks, and cutting requires strong cutting force and impact resistance. The aluminum cutting circular saw blade can withstand large loads with high hardness and toughness, and quickly cut the aluminum bars. The sawtooth chip groove design dissipates heat in time to prevent the aluminum bars from overheating and affecting performance, while extending the life of the saw blade. It is used in mechanical factories to cut aluminum bars, which can be processed efficiently and stably, providing high-quality blanks for subsequent processes.

5.Application in copper tube and copper rod cutting

Copper is soft and easy to stick to the knife, and the surface is rough after cutting. The carbide cutter head uses a coating to reduce friction and prevent sticking, and the sharp edge can achieve rapid cutting with a high surface finish; its wear resistance can also ensure stability when cutting high-hardness copper alloy rods, which is suitable for the processing needs of electrical, bathroom and other industries.