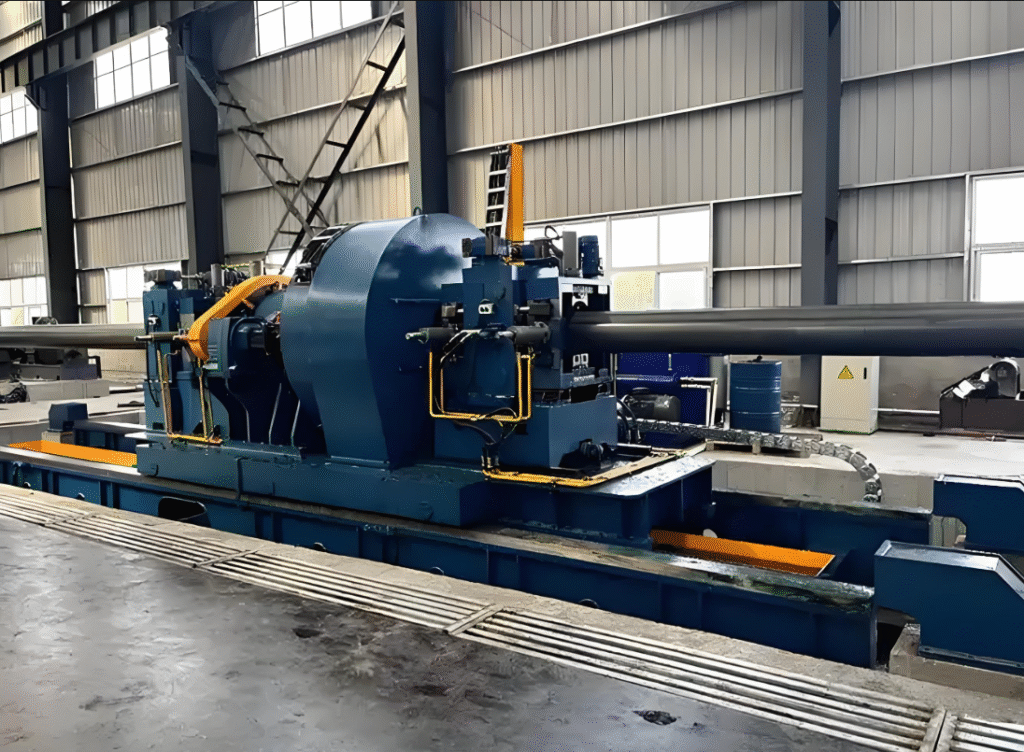

Contour milling cutting is a professional machining process that relies heavily on contour milling saw blades. These saw blades are made of high-quality cemented carbide, a material that endows them with extremely high hardness and excellent wear resistance. This enables the saw blades to easily handle the contour milling operations of large-diameter, thick-walled pipes, and they exhibit exceptionally outstanding performance in scenarios such as on-line orbital sawing of pipes—where strict requirements are imposed on sawing precision and efficiency. Even when operating under high-frequency, high-load conditions for an extended period, contour milling saw blades can still maintain stable and reliable cutting performance, providing strong support for continuous production and processing.

During the high-speed rotating cutting process, contour milling saw blades demonstrate extremely strong operational stability. When the cutting speed is maintained within a relatively efficient range of V=350∼400m/min and the feed rate is kept at 0.04∼0.12mm/tooth, the overall performance of the saw blade can reach its optimal state. At this point, it not only ensures efficient cutting operations and significantly improves processing efficiency but also remarkably enhances cutting precision, allowing the processed pipes to better meet the technical requirements in terms of size, shape, and other aspects.

Furthermore, contour milling saw blades possess strong continuous operation capabilities. When combined with a highly precise feed control system, they can achieve extremely accurate control over the feed rate for each operation. This strictly limits the error during the cutting process to a very small range, greatly reducing the pipe scrap rate. In turn, this helps enterprises save a substantial amount of production costs and improve their economic efficiency.

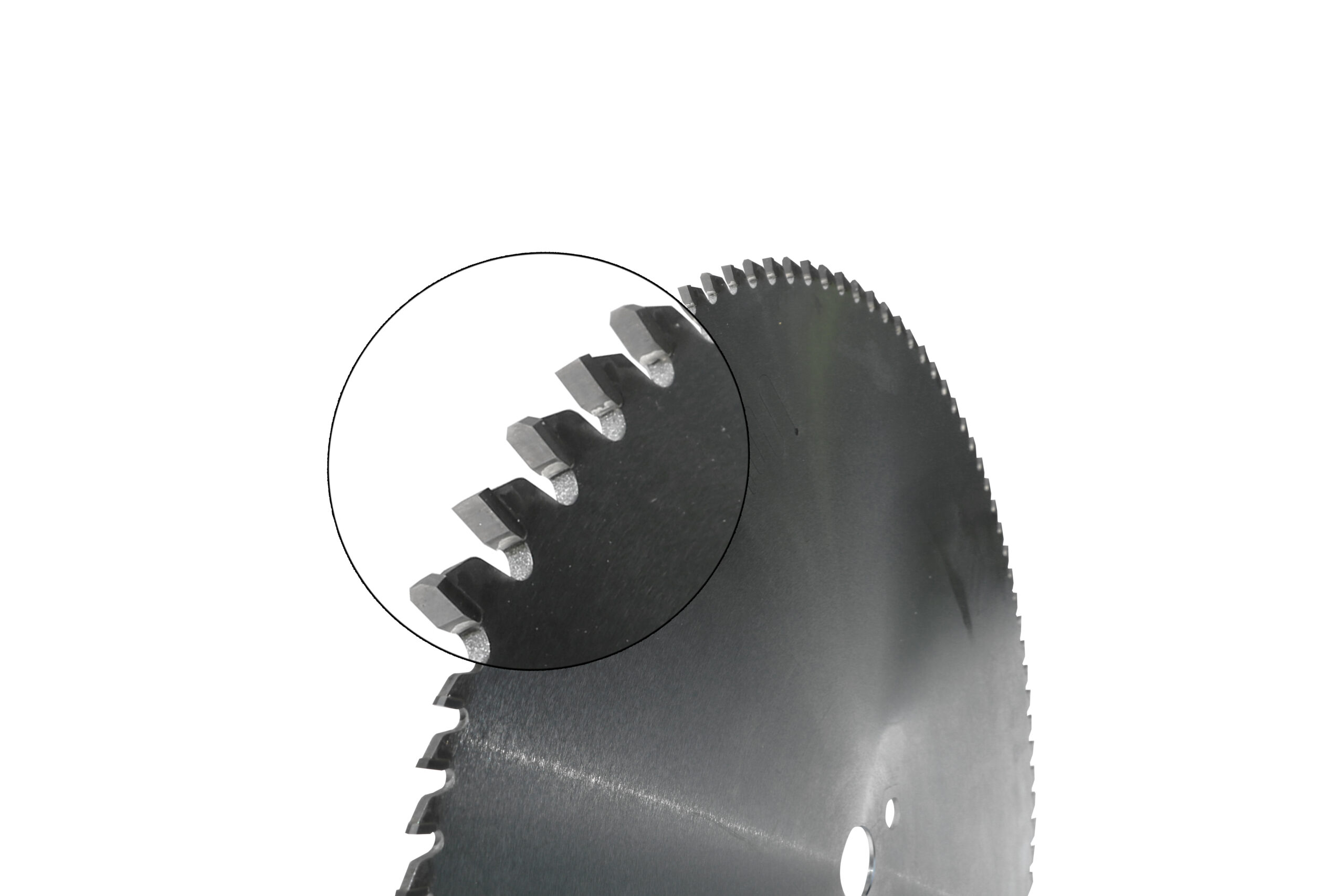

Contour milling saw blades have an extremely wide range of applicable pipe materials. They can perform stable and efficient cutting operations on many common types of pipes, such as carbon steel pipes, stainless steel pipes, and alloy steel pipes. During the cutting process, the tooth profile of the saw blade has undergone elaborate optimization design. When combined with the inherent advantages of the cemented carbide material, this makes the entire cutting process much smoother. It not only effectively reduces the resistance generated during cutting, further improving cutting efficiency and quality but also minimizes the heat produced in the cutting process. This reduces thermal damage to both the pipes and the saw blade, extends the service life of the saw blade, and at the same time, better ensures that the performance of the pipes remains unaffected.

After the cutting is completed, the cross-section of the pipe appears smooth and flat, requiring almost no secondary processing. This significantly shortens the production cycle, enabling enterprises to launch their products into the market more quickly. Precisely because of these advantages, contour milling cutting and contour milling saw blades hold crucial and widely applicable value in numerous fields such as pipe processing and mechanical manufacturing. They strongly assist relevant enterprises in improving production efficiency and product quality, helping them gain a more favorable position in the fierce market competition.