Traditional Saw Blade Cleaning VS Ultrasonic Saw Blade Cleaning

The price of traditional saw blade washing equipment is around RMB 20,000 (CNY) per unit. Previously, three units were used, each with a single function: hot water steaming and brush cleaning. The disadvantage is that the water needs to be changed regularly. If not managed properly, there is a possibility of repeated cleaning with dirty water, resulting in inadequate cleaning. Generally, this equipment is sufficient for small businesses.

However, our company uses fully automatic ultrasonic cleaning equipment. The price is around ¥300,000 (CNY), it has an automatic water supply and drainage, and the water quality is easy to control. There are 8 cleaning chambers, and one device can handle 8 cleaning steps. Why do saw blade factories care so much about the cleaning process? Because the cleanliness of the saw blade surface is related to the next process, surface coating. The cleaner the surface of the saw blade is, the higher the bonding between the target particles in the high-temperature chamber and the saw blade will be during the coating process. In this way, the surface coating of the finished saw blade will be more wear-resistant and less likely to fall off during use.

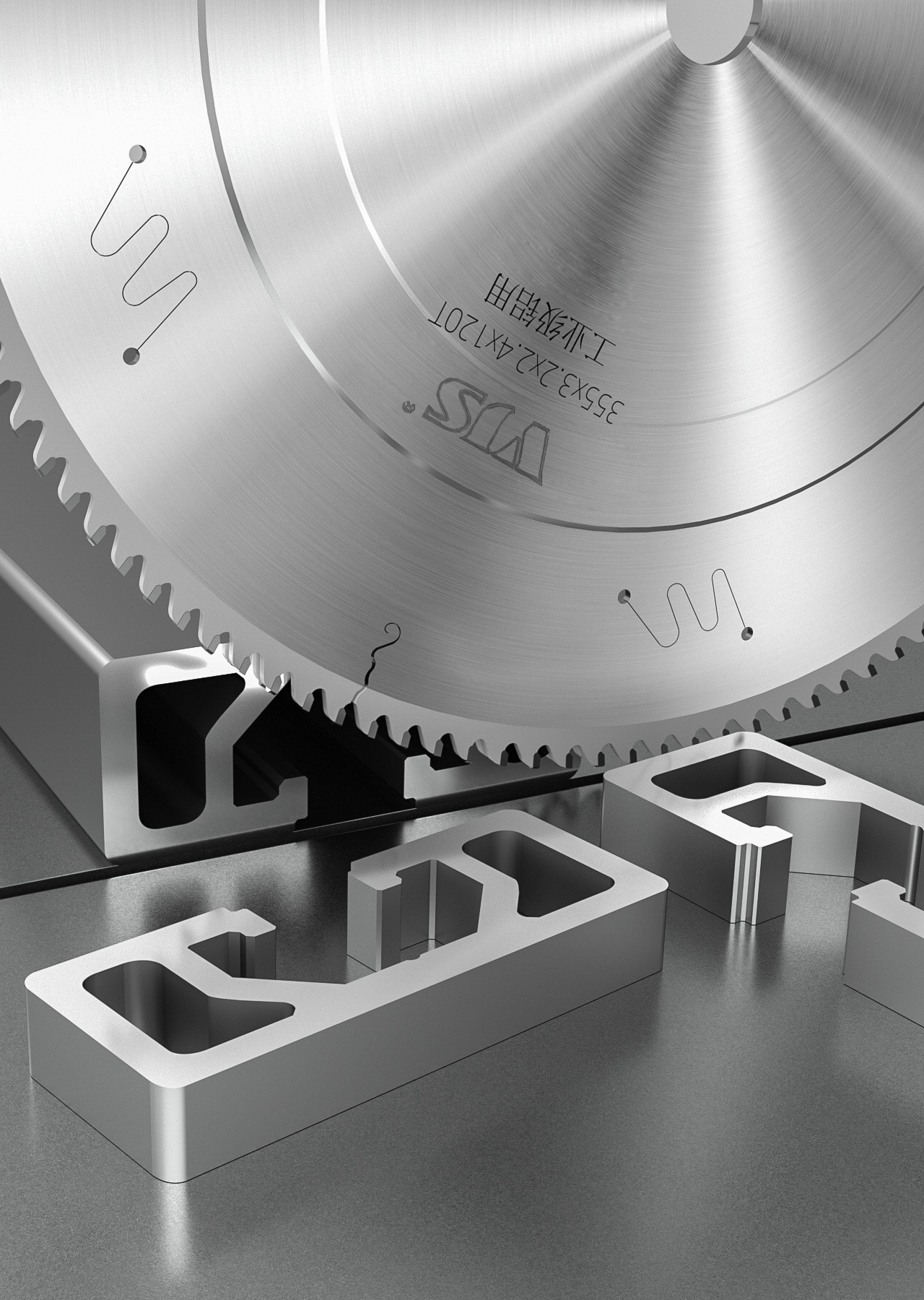

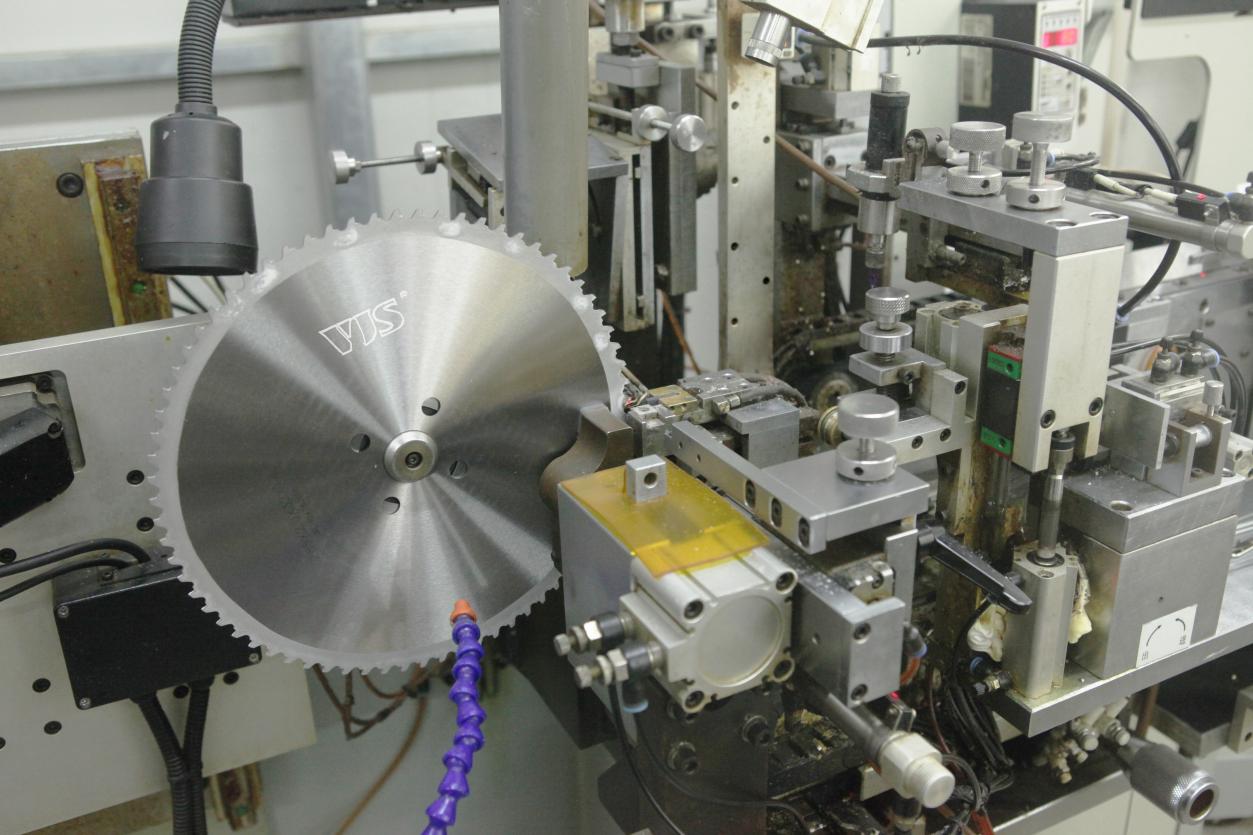

Traditional Gear Grinding Machine VS Five-axis Fully Automatic Gear Grinding Machine

The price of a traditional semi-automatic gear grinding machine is around ¥7000 (CNY). Each device can perform grinding and chamfering, but lacks the grooving function. The operation of switching functions is cumbersome, and the cutting edge of the grinding wheel needs to be adjusted according to the shape of the saw teeth during the grinding process. It is difficult for a master without 5 years of experience to grasp this step accurately. The chamfer thickness is typically about one-third of the tooth's thickness. Thinner teeth are more difficult to discern with the naked eye, often resulting in chamfers that are too large or too small. A high-quality saw blade, with imprecise tooth cutting, can't achieve its maximum cutting power, a real shame.

Our 5-axis fully automatic tooth cutting equipment costs around RMB 160,000 (CNY). Each device has tooth-cutting, chamfering, and grooving functions. The switching function is easy to operate, and the chamfering thickness is CNC-controlled. Even the thinnest saw blades can be accurately cut. We serve countless physical factories, and the cutting angles of different types of equipment and the saw tooth angles required for cutting different materials are accurately recorded and retained, so that when serving new customers, we can use the optimal saw tooth parameters and maximize the cutting force of the saw blade.

Cheap Coating Equipment VS Expensive Coating Equipment

Traditional coating equipment costs around ¥500,000 (CNY). Its functional shortcomings are that the high-temperature chamber is smaller in size, the number of saw blades that can be loaded is limited, and the cost is higher. The high-temperature reaction time is shorter, the bonding degree between the surface target particles and the saw blade is lower, and the surface coating of the saw blade is more likely to fall off after it is finished. Furthermore, using traditional cleaning equipment significantly reduces durability.

The latest coating equipment costs around ¥5 million (CNY). The high-temperature chamber is larger in size and can load more saw blades, saving costs; the high-temperature reaction time is longer, the surface target particles and the saw blade are more closely bonded, and the surface coating of the finished saw blade is durable and wear-resistant and will not fall off. Coupled with the ultrasonic cleaning process, the wear resistance is greatly improved, and the saw blade teeth can be processed first and then coated. After testing, this process can increase the wear resistance of each saw tooth by 3 times compared with the original process.

Traditional Grinding Machine VS Our Grinding Machine

Traditional grinding machines cost about ¥20,000 (CNY) each, and each machine has different processes, so multiple machines are required to complete a process. A significant drawback is that the step sizes of each saw blade vary, resulting in inconsistent results from individual operators. This also results in inaccurate saw blade thickness.

However, our company uses a custom-developed grinding machine, priced at ¥300,000 (CNY) per unit. The thickness of the steps on the front and back of each saw blade is more accurate, and one saw blade can handle multiple processes. The operation is simple, the defective rate is reduced, and costs are saved. We have also applied for a certificate for independent research and development. To prevent piracy, we do not provide images of the entire machine; only partial images are available.

Magnifying Glass Inspection of Unsharpened Saw Blades VS Sawtooth Inspection After Sharpening

After the traditional semi-automatic gear grinding machine is finished, there is almost no inspection process. Some of the saw teeth are not even sharp. They are directly packaged and shipped to customers for use. It is common that the teeth become dull after just a few cuts.

In order to avoid this situation, our company uses a magnifying glass from the fine machining industry to inspect saw teeth. The defects of each saw tooth are clearly visible, and a professional algorithm is used to calculate the degree of compliance of the saw tooth angle. When the saw blade is used in different equipment and cuts different materials, the required saw tooth angle is accurately corrected under the algorithm to ensure the sharpness of each saw tooth and allow each saw blade to exert its maximum cutting force. This applies not only to new saw blades, but also to resharpening older blades. Many older saw blades have subtle cutting artifacts on their teeth, nearly invisible to the naked eye. These artifacts are clearly visible under an industrial magnifying glass, allowing for easy correction during the grinding process.

Runout Before Leveling VS Micrometer Measurement of Runout After Leveling

Unleveled saw blades have significant runout, making them virtually unusable. Once mounted on equipment, significant runout can lead to blade breakage during cutting, and the verticality of the cut material can be inaccurate.

However, our company's saw blades are manually leveled before they are finished by a master with 15 years of leveling experience, ensuring that the runout of the saw blade is within the range of 2-12 wires, ensuring that every saw blade received by the customer is of the quality of craftsmanship with meticulous craftsmanship. After being used many times, the saw blade can also be corrected for flatness, making your old saw blade look brand new and creating greater profits for the company again.

Important Notice:

This document summarizes our company's technological research and development and process practices. It constitutes core technical information and an important internal document. Its use is limited to authorized internal production, quality inspection, technical exchanges, and other areas. Any entity or individual may not reproduce, excerpt, or disseminate the contents of this document without our written permission. Once plagiarism or infringement is discovered, our company will pursue legal liability in accordance with the law.