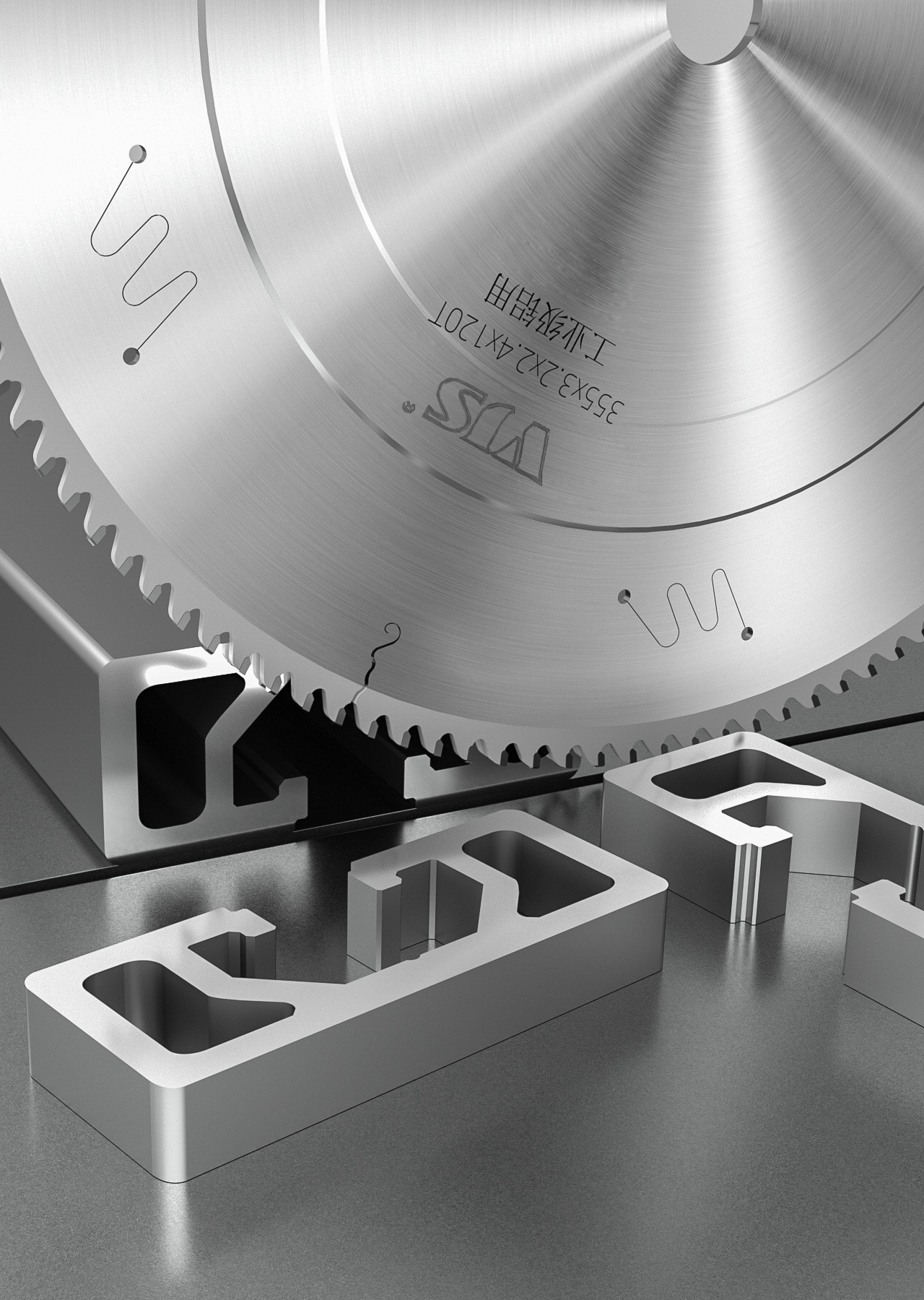

In the metal processing industry, aluminum saw blade tooth loss seriously affects production efficiency, increases costs and safety hazards. VJS Saw Industry, which has been deeply engaged in the field of saw blade manufacturing, analyzes the main causes of tooth loss and provides solutions for you, while answering the questions that users are concerned about: Can aluminum alloy saw blades continue to be used if they lose teeth during use?

Material and craftsmanship are the key. Some manufacturers use inferior raw materials and backward welding technology, which leads to insufficient strength of saw blades and easy tooth loss. VJS Saw Industry selects imported high-purity cemented carbide and adopts vacuum welding technology to ensure that the blade head and the base are firmly combined, eliminating tooth loss from the source.

Improper operation also exacerbates the wear. Cutting different metals without adjusting parameters, such as high-speed cutting of soft aluminum alloys or high feed rate cutting of stainless steel, will accelerate the wear of the saw blade.

Lack of equipment maintenance cannot be ignored. Vibration of old equipment, failure to clean debris and lubricate in time will accelerate the aging of saw blades. VJS Saw Industry provides after-sales maintenance services, covering equipment commissioning and saw blade maintenance, to ensure stable operation of saw blades under complex working conditions.

Regarding whether aluminum alloy saw blades can continue to be used after teeth are lost, VJS Saw Industry Technical Experts said that once a saw blade has lost teeth, it is not recommended to continue using it in principle. Losing teeth will break the original dynamic balance of the saw blade, and may cause violent vibrations during high-speed rotation and cutting, which will not only reduce cutting accuracy, cause rough cutting surfaces and dimensional deviations, but also cause additional damage to the cutting equipment and shorten the service life of the equipment. More importantly, continuing to use saw blades with lost teeth poses a huge safety hazard. The unstable operating state may cause the remaining blades to fall off, and the flying metal fragments can easily cause personal injury to the operator. If the tooth loss is minor and the cutting requirements are not high, the saw blade must be fully inspected and repaired by a professional, and it can only be used with caution after re-balancing.

Choosing VJS Saws means choosing efficient and durable cutting guarantee. We continue to innovate to help metal processing companies reduce costs and increase efficiency, open up greater value space, and at the same time provide users with more professional saw blade usage knowledge and suggestions.