About Us

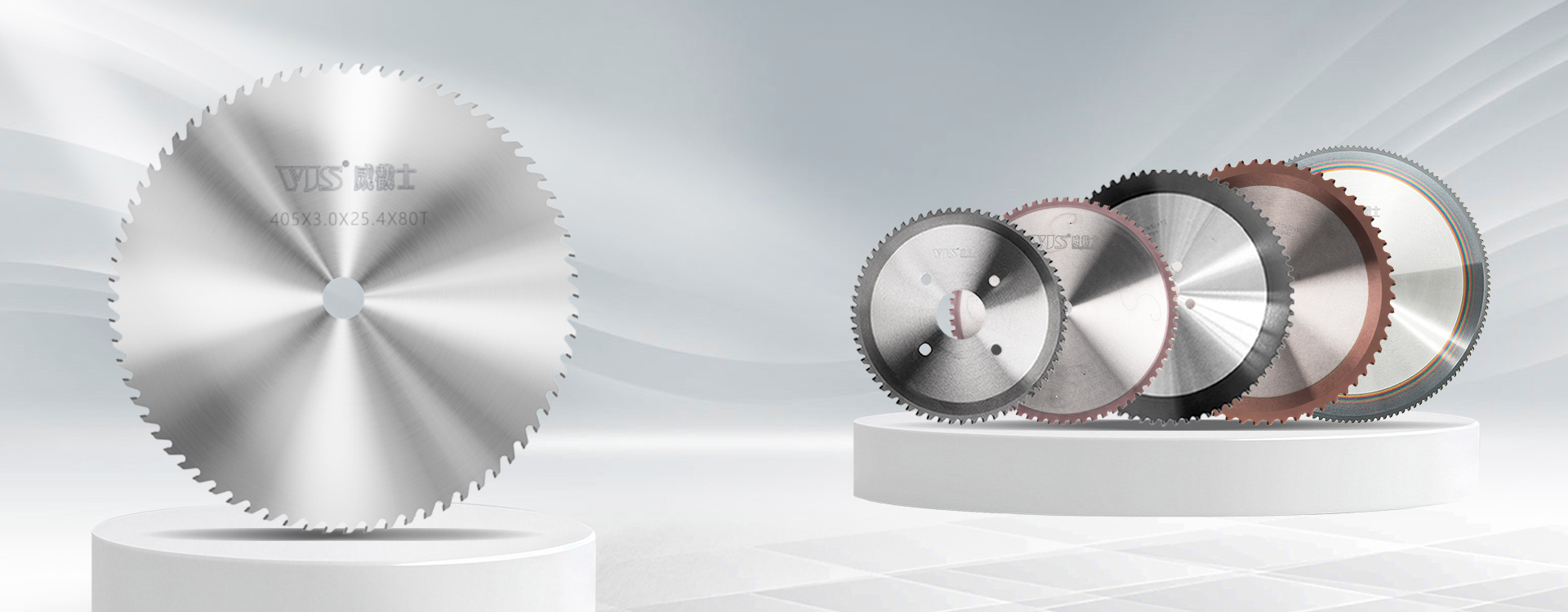

VJS Saw Industry Technology (jiangsu) Co., Ltd.

We are a modern enterprise focusing on the sawing industry, integrating R&D, production, sales and service. Since its establishment in August 2021, the company has built a complete and advanced production system by continuously studying and innovating in sawing technology. The factory now has more than 100 employees and an annual turnover of 50 million.

Our products cover a variety of metal application fields, used for cutting metal materials such as plain carbon steel, low/medium carbon steel, copper, iron, aluminum, stainless steel, etc. These saw blades are suitable for online, offline, high-speed circular saws, aluminum cutting machines, desktop cold saws, cold saw cutting machines, copy milling saws and other cutting equipment.

At the same time, in order to meet the diverse needs of different customers, the diameter, thickness, number of teeth and other parameters of the saw blade can be customized according to the specific requirements of the customer to ensure that every customer can obtain sawing products suitable for their own industry.

With excellent product quality and advanced professional technology, our products are sold well in domestic and foreign markets. The company will continue to adhere to the quality-oriented and customer-first development philosophy, increase investment in research and development, explore new technologies and new materials, and create higher-quality saw blades.

Application Field

From high-speed production lines to specialized material processing, our advanced saw blades deliver unmatched performance across critical industries—ensuring efficiency, accuracy, and durability in every cut.

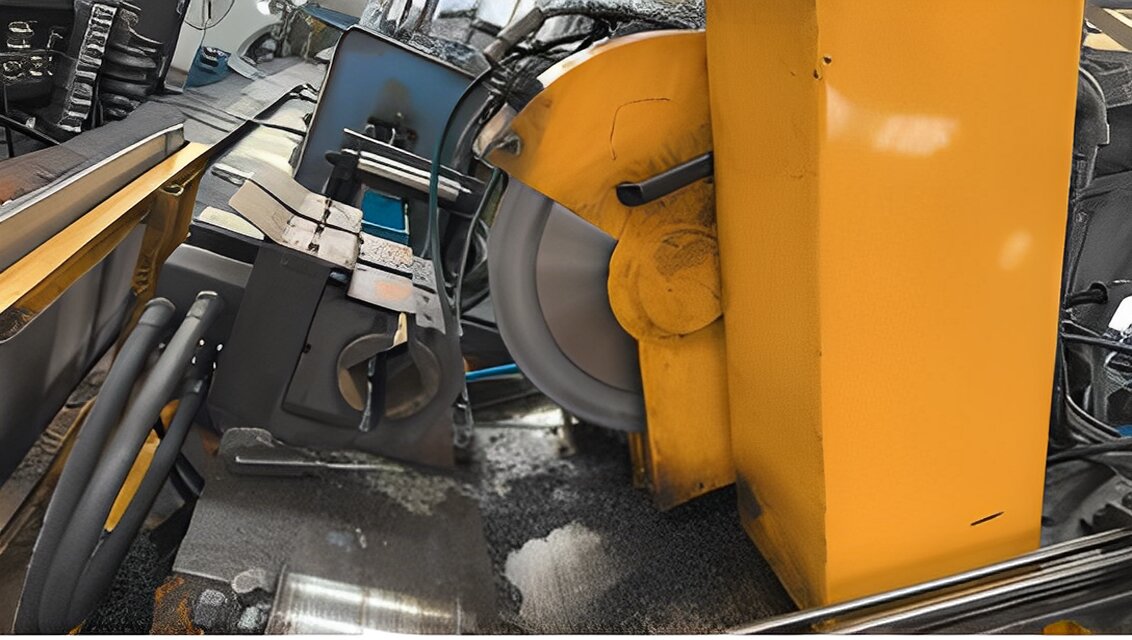

Offline Cutting Equipment

High-speed steel saw blades are suitable for cutting alloy steel, stainless steel, high-strength steel, iron, copper and other metal materials, and can be used with various offline equipment such as pipe cutting machines.

Online Cutting Equipment

The saw blade of the online cutting flying saw is used for sawing metal materials such as iron and steel hollow round pipes/square pipes, and iron/steel profiled sections on the welded pipe production line, enabling high-speed dynamic tracking cutting.

High Speed Circular Saw Machine

Metal ceramic cold cutting saw blades are suitable for high-speed metal circular saw machines. They can cut medium/low carbon steel billets, stainless steel billets, steel plates and bearing steel. They are widely used in automated cutting scenarios in industries such as steel metallurgy, machinery manufacturing, aerospace, chemical and medical.

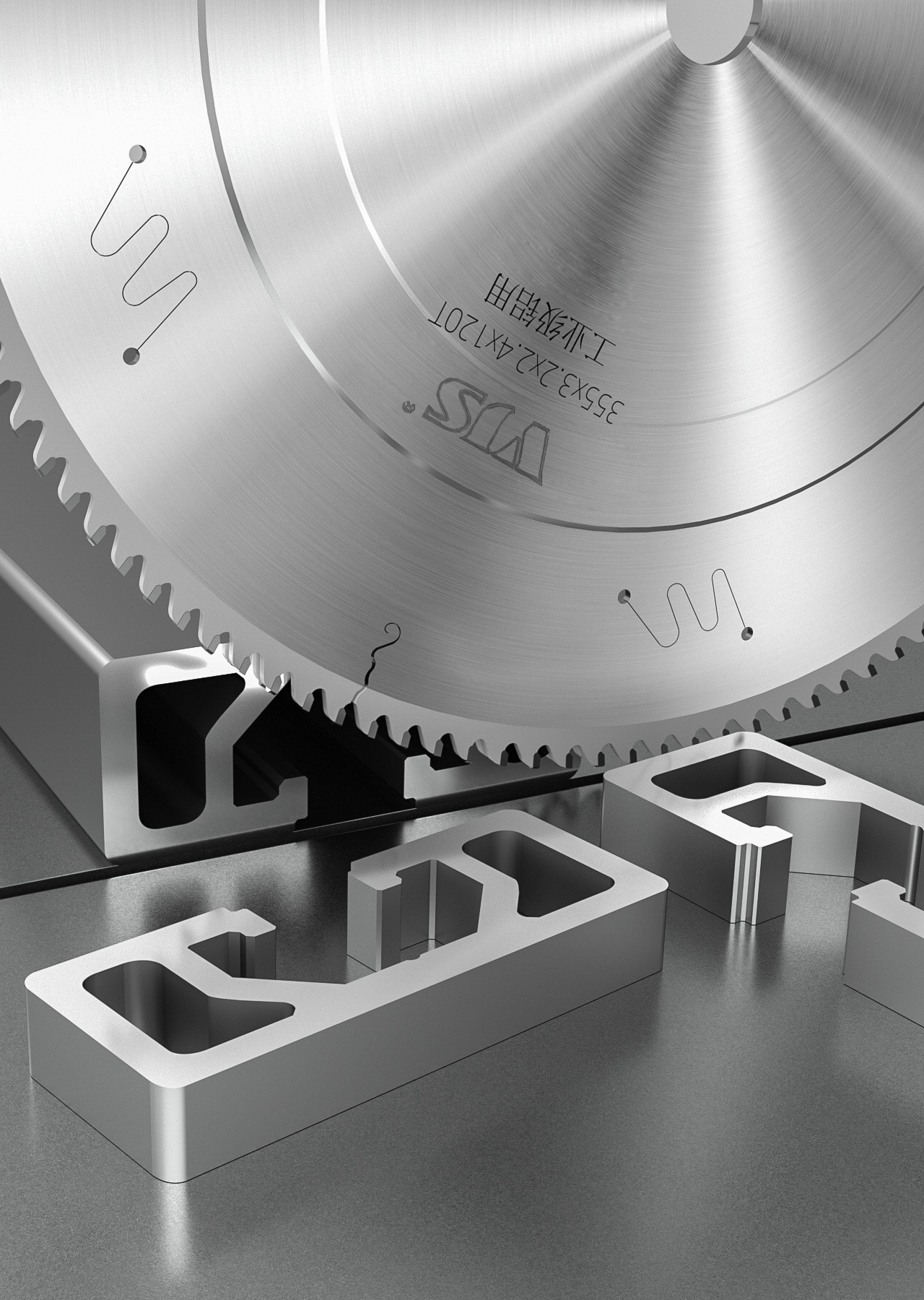

Desktop Cold Cut Saw

Ironworker cold-cutting saw blades can efficiently cut various steel profiles and pipes, such as rebar, angle steel, channel steel, I-beams, and steel pipes. They are widely used in scenarios including construction steel structure projects, mechanical parts manufacturing, pipeline installation works, and metal recycling processes, and are compatible with bench-type cold-cutting saws.

Aluminum Cutting Machin

Circular saw blades for aluminum cutting can efficiently cut non-ferrous metal materials such as aluminum pipes, aluminum sheets, aluminum profiles, aluminum bars, copper pipes and copper bars. They are suitable for aerospace, automotive manufacturing, electronics and electrical appliances, architectural decoration, bathroom hardware and other scenarios, and are compatible with equipment such as aluminum cutting machines.

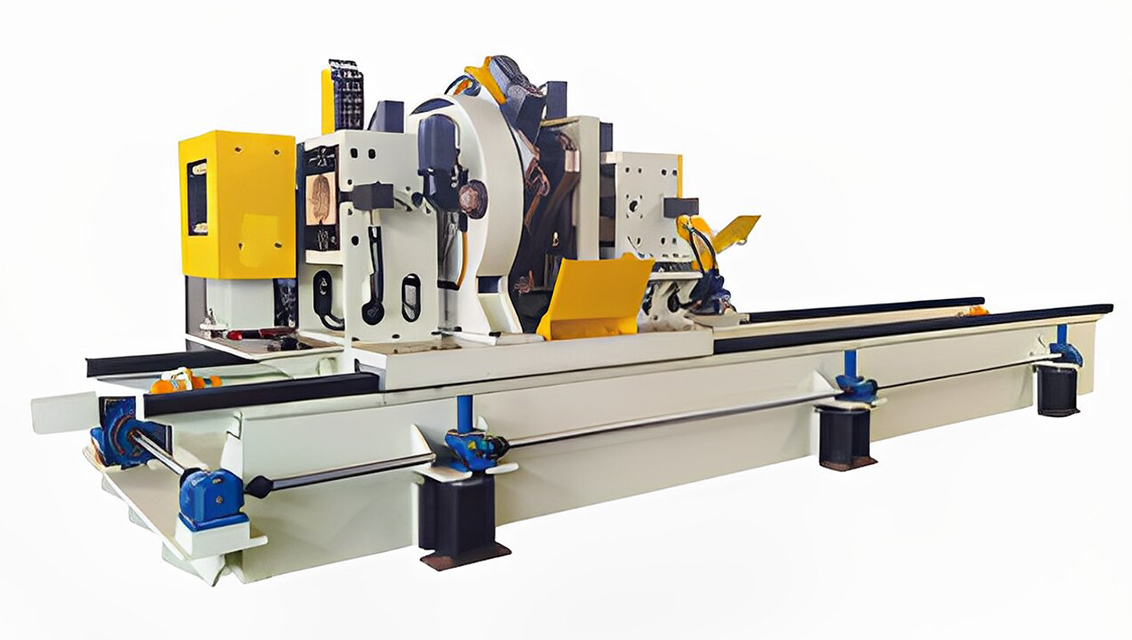

Copy Milling Saw Machine

The profiling milling cutting saw blade can cut carbon structural steel, low-alloy high-strength steel, and steel for oil casing pipes. It is used in scenarios such as oil pipeline bevels and special-shaped steel structure parts, and is compatible with CNC profiling milling equipment. It can follow the contour to cut complex shapes and meet precision requirements.

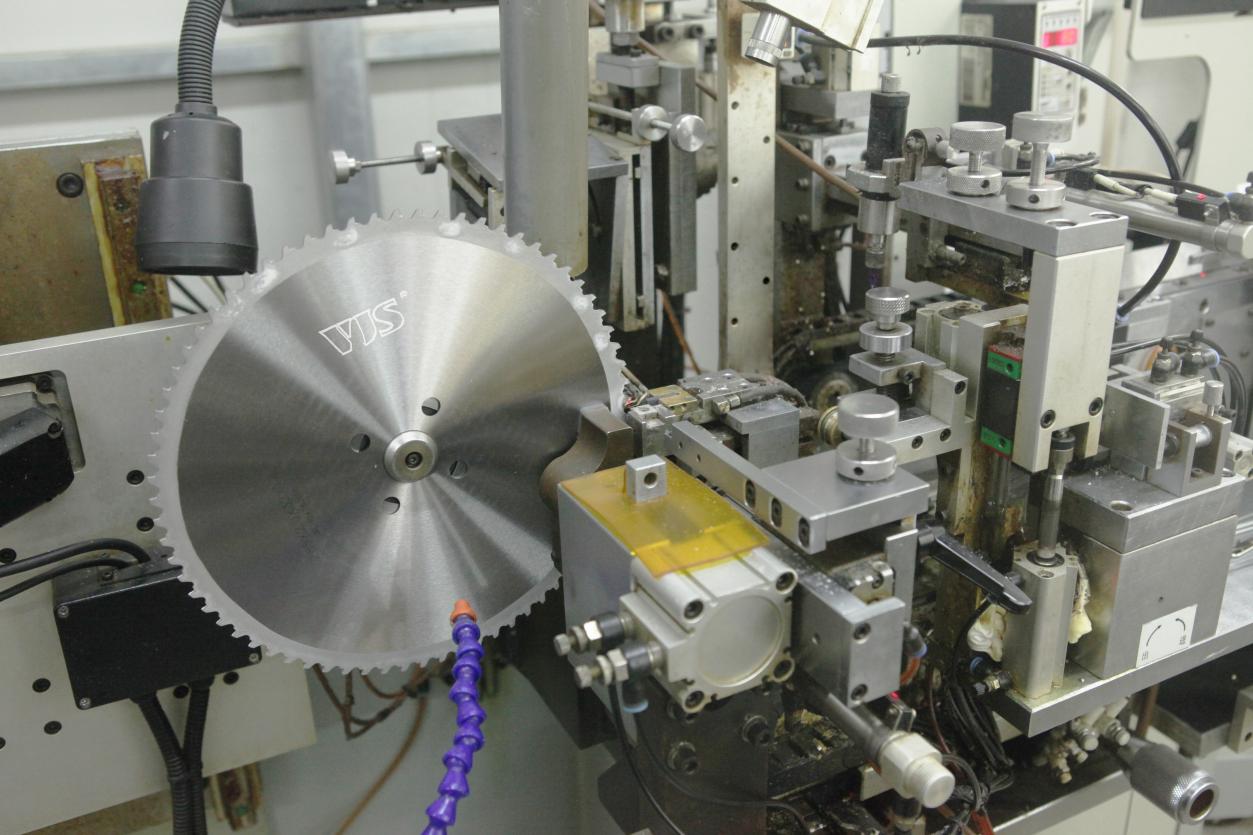

Cutting Machine

Tungsten steel saw blades are suitable for cutting machines with a speed of 1,500 to 3,000 revolutions per minute. They can cut stainless steel pipes, copper pipes, aluminum pipes, iron pipes, capillary tubes, etc., and are suitable for precision pipe processing in medical devices, electronics, automotive and other industries.

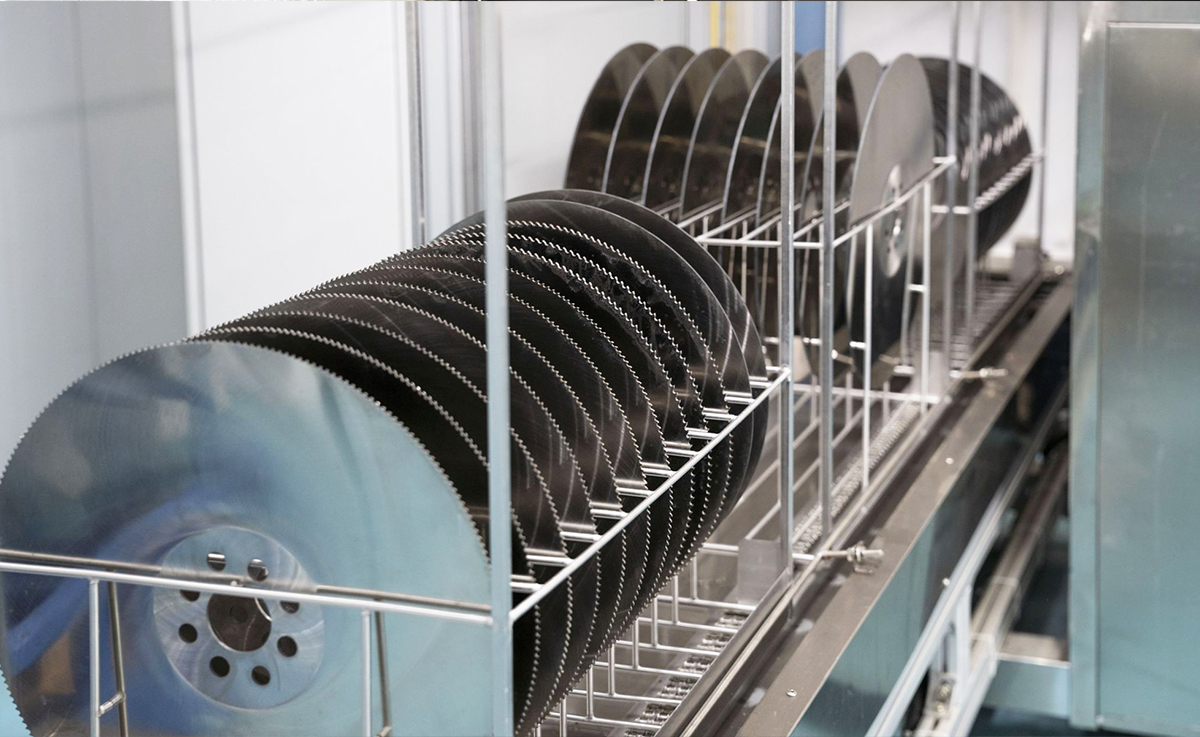

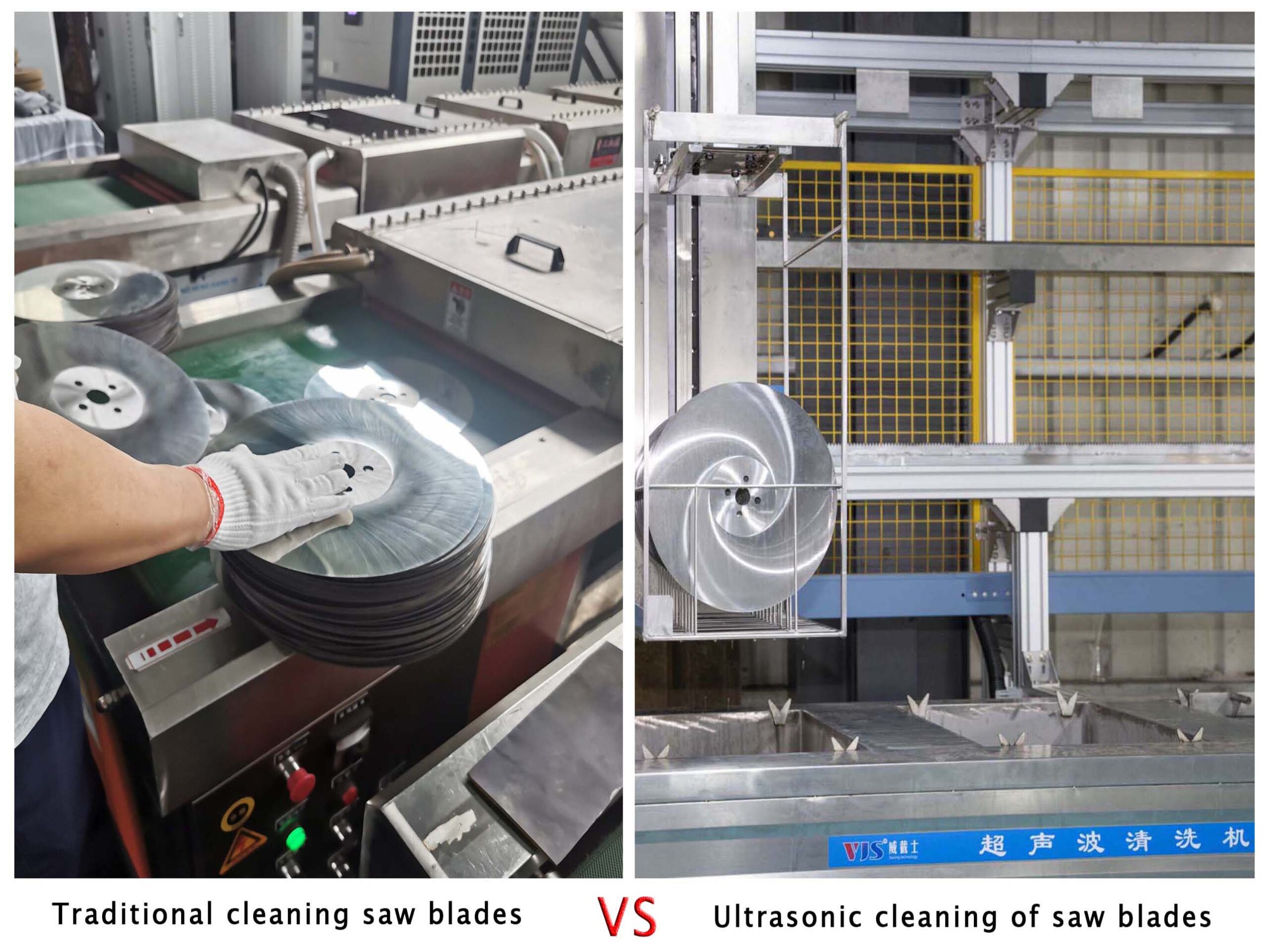

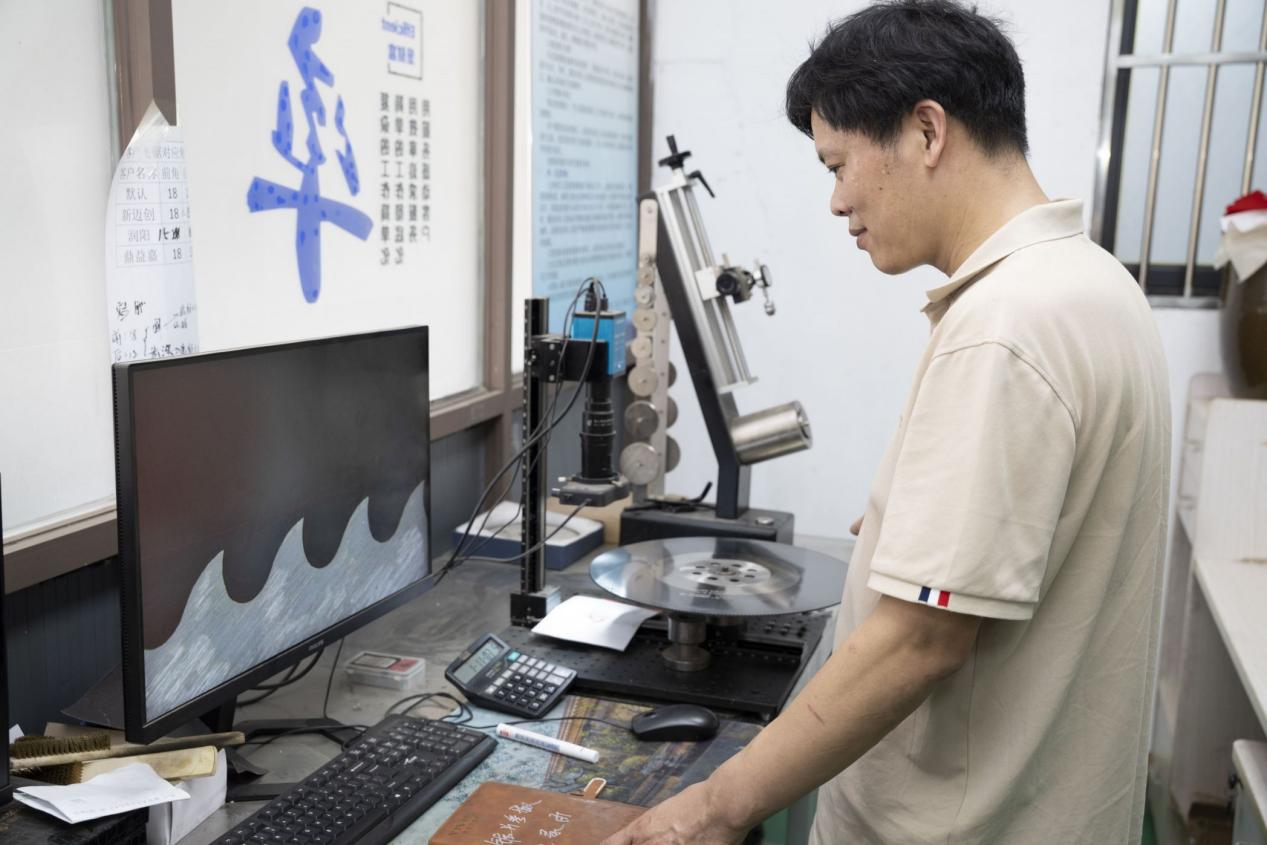

Factory Processing Procedure

In our state-of-the-art factory, each saw blade undergoes a rigorous production process that combines automated precision with artisan craftsmanship to provide an industrial-grade cutting solution.

Process Control

Ensure that the hardness, toughness and life of each saw blade reach industrial-grade precision.

Trial Cutting

Free trial cutting accurately matches the working conditions.

Grinding Service

Professional saw blade grinding service, tool life performance is like new.

Expert Guidline

Customized saw blade selection plan to improve cutting efficiency and reduce waste.

Excellent Factory

ISO factory certification, full control from R&D to production.